Portugal’s construction industry is at a critical juncture. Rising building costs, a shortage of skilled labor, and lengthy construction timelines are straining the country’s ability to meet its urgent housing needs. Against this backdrop, industrial prefabrication—using modular building techniques—offers a promising path forward. A recent German study by BauInfoConsult highlights the growing role of serial construction using prefabricated elements, particularly in concrete. But to truly transform the housing landscape in Portugal, both concrete and wood modular systems must be embraced as equally valuable solutions.

Germany’s construction sector has seen significant growth in the use of prefabricated concrete panels, particularly for walls, floors, and structural components. Concrete’s durability, fire resistance, and cost predictability make it a natural choice for large-scale, standardized buildings like housing complexes, schools, and hospitals. In the Portuguese context—where seismic resilience is a priority—concrete structures, when properly certified, offer a robust and tested option.

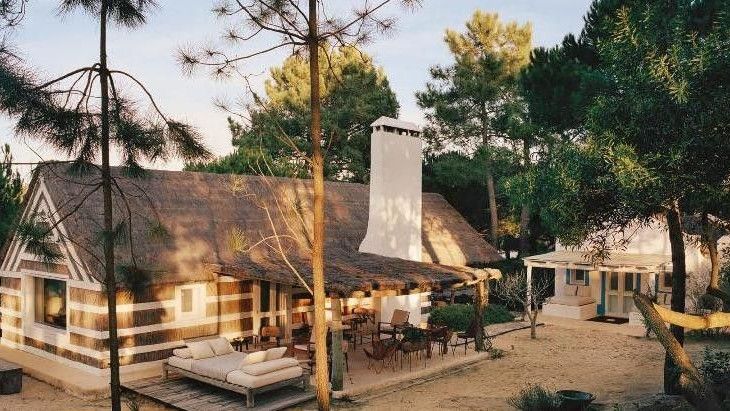

However, wood is rapidly gaining momentum across Europe, particularly in the Netherlands and the UK, where sustainable construction is a growing priority. Engineered wood products, such as cross-laminated timber (CLT), now meet stringent structural and seismic standards, offering a lightweight yet strong alternative to concrete. Wood construction has a smaller carbon footprint, is easier to transport, and can be prefabricated with high precision—reducing waste and speeding up timelines. For Portugal, where forest resources are abundant and underutilized, this opens opportunities for both housing innovation and local economic development.

Rather than viewing concrete and wood as competitors, Portugal should see them as complementary. Each has strengths that align with different types of projects and local conditions. Concrete may be best suited for high-density urban areas where fire resistance and load-bearing capacity are essential, while wood can offer speed and sustainability in suburban or rural developments, or in vertical extensions of existing buildings.

What both systems require is a supportive regulatory environment. Streamlined permitting processes, updated building codes that reflect modern prefabrication technologies, and incentives for pilot projects are key to unlocking their full potential. Certification standards already exist to ensure seismic safety for both materials—Portugal need only implement and promote them.

In conclusion, modular housing, whether built in concrete or wood, is not just a technical fix but a strategic response to the country’s structural housing challenges. Embracing both materials, Portugal can create a flexible, resilient, and sustainable construction future that meets today’s urgent needs while preparing for tomorrow’s demands.

Paulo Lopes is a multi-talent Portuguese citizen who made his Master of Economics in Switzerland and studied law at Lusófona in Lisbon - CEO of Casaiberia in Lisbon and Algarve.